European standards for safety shoes are defined by the European Committee for Standardization (CEN). These standards ensure that safety footwear provides adequate protection for various working environments. Here are the key European standards for safety shoes, along with detailed explanations of each:

EN ISO 20345:2011 – Safety Footwear

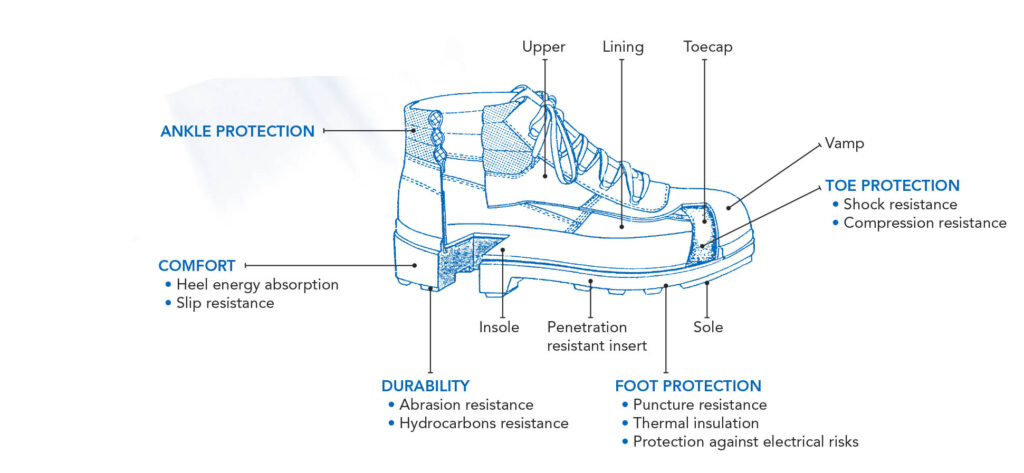

This standard specifies the basic and additional (optional) requirements for safety footwear used for general purposes. Footwear that complies with this standard provides protection against various hazards that can be encountered in the workplace. Key features include:

- Toe Cap: Must withstand a 200-joule impact.

- Slip Resistance: Classified as SRA (tested on ceramic tile with dilute soap solution), SRB (tested on smooth steel with glycerol), or SRC (both SRA and SRB).

- Anti-static Properties: Prevents the build-up of static electricity.

- Energy Absorption: Heel area must absorb energy.

- Fuel Oil Resistance: Sole must resist degradation when in contact with fuel oil.

EN ISO 20346:2014 – Protective Footwear

This standard is similar to EN ISO 20345 but with a lower level of protection. Protective footwear must withstand a 100-joule impact rather than the 200-joule requirement of safety footwear.

EN ISO 20347:2012 – Occupational Footwear

Occupational footwear under this standard is designed for working environments where there is no need for protection against mechanical risks (impact or compression). It focuses on comfort and safety features such as slip resistance and antistatic properties.

Additional Safety Classifications

Within these standards, safety shoes can be classified further based on specific additional properties:

- SB: Basic safety footwear with a 200-joule toe cap.

- S1: SB features plus antistatic properties, energy absorption in the heel, and a closed seat region.

- S1P: S1 features plus penetration resistance.

- S2: S1 features plus water resistance.

- S3: S2 features plus penetration resistance and cleated outsole.

- S4: Waterproof footwear made entirely of polymer or rubber, with antistatic properties and energy absorption in the heel.

- S5: S4 features plus penetration resistance and cleated outsole.

Other Markings and Symbols

- CI: Cold Insulation

- HI: Heat Insulation

- HRO: Heat Resistant Outsole

- WR: Water Resistance

- WRU: Water Penetration and Absorption Resistance

- M: Metatarsal Protection

- CR: Cut Resistance

- AN: Ankle Protection

- E: Energy Absorption of Seat Region

- A: Antistatic

- P: Penetration Resistance

- FO: Fuel Oil Resistant Outsole

EN ISO 13287:2012 – Slip Resistance

This standard specifies methods to test and evaluate the slip resistance of safety, protective, and occupational footwear.

EN ISO 20344:2011 – Test Methods

This standard describes the methods for testing the properties of safety, protective, and occupational footwear to ensure they meet the required standards. It includes tests for impact resistance, compression resistance, slip resistance, penetration resistance, and more.

These standards help ensure that safety shoes provide the necessary protection for various industrial and occupational hazards, enhancing worker safety and comfort.