Selecting the right safety glasses is crucial to ensure adequate protection, comfort, and performance in your specific environment. Here’s a detailed guide on how to choose the right safety glasses:

1. Identify the Hazards

Mechanical Hazards:

- Impact Protection: If you’re working in an environment with flying debris or particles, choose safety glasses that meet at least the F (low energy impact) standard of EN 166. For higher risks, consider B (medium energy impact) or A (high energy impact) ratings.

Chemical Hazards:

- Splash Protection: For environments with chemical splashes, select goggles that provide a tight seal around the eyes.

- Vapor Protection: If there’s exposure to harmful vapors or gases, choose goggles designed to prevent ingress of these substances.

Radiation Hazards:

- UV Protection: If working outdoors or with sources of UV light, select lenses with UV filters. Look for markings indicating UV protection according to EN 166.

- Infrared Protection: For tasks involving infrared radiation, choose glasses with appropriate IR filters.

- Welding Protection: If involved in welding, use safety glasses or goggles with the appropriate shade number to protect against intense light and radiation.

Dust and Fine Particles:

- Dust Protection: In dusty environments, choose goggles or glasses that offer a seal to keep out fine particles.

2. Consider the Environment

Indoor vs. Outdoor:

- Indoor Use: Clear lenses are typically sufficient for indoor environments.

- Outdoor Use: Tinted lenses or photochromic lenses (that adjust to changing light conditions) are beneficial for outdoor use.

Lighting Conditions:

- Low Light: Amber or yellow-tinted lenses can enhance contrast in low-light conditions.

- Bright Light: Gray or mirror-coated lenses can reduce glare and provide comfort in bright conditions.

3. Evaluate Optical Clarity

Optical Class:

- Class 1: Suitable for continuous use; provides the best optical quality.

- Class 2: Suitable for intermittent use.

- Class 3: Suitable for occasional use; may have minor optical distortions.

4. Check for Comfort and Fit

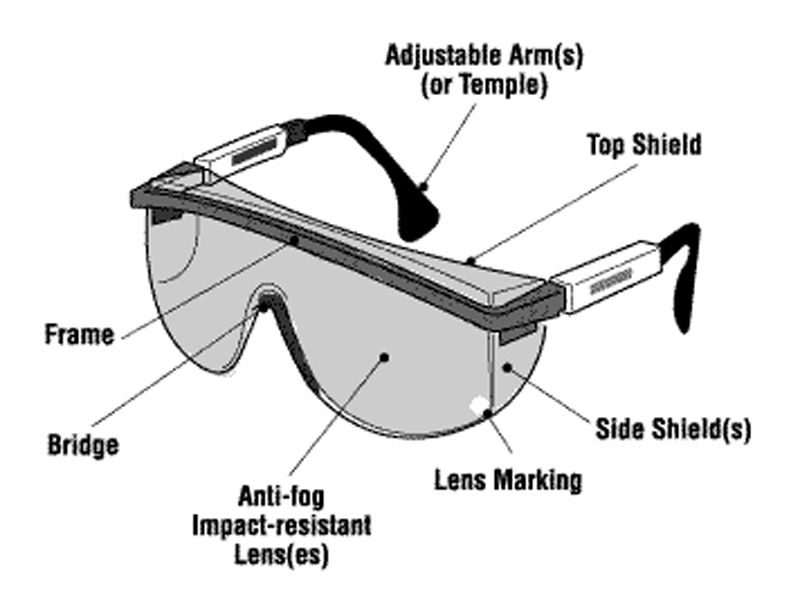

Adjustability:

- Look for adjustable features like temple arms and nose pads to ensure a snug and comfortable fit.

Weight:

- Lighter glasses reduce fatigue, especially during prolonged use.

Ventilation:

- For goggles, ensure adequate ventilation to prevent fogging.

5. Verify Compliance and Certification

Markings:

- Check for EN 166 markings to ensure the glasses meet the necessary safety standards.

- Look for additional markings indicating specific protections (e.g., UV, IR, impact resistance).

6. Specialty Features

Anti-Fog and Anti-Scratch Coatings:

- These coatings can enhance durability and usability, especially in humid environments or when transitioning between different temperatures.

Prescription Lenses:

- If you need corrective lenses, look for safety glasses that can accommodate prescription inserts or have built-in prescription lenses.

7. Assess Durability and Maintenance

Material Quality:

- Ensure the glasses are made from durable materials such as polycarbonate or Trivex for impact resistance.

Ease of Maintenance:

- Choose glasses that are easy to clean and maintain to ensure longevity and continued protection.

8. Consider Style and Personal Preference

Design:

- Choose a design that you are comfortable with and that you are more likely to wear consistently.