Here’s a comprehensive Construction PPE Guidance based on global standards, risk-specific requirements, and best practices, synthesized from the provided research:

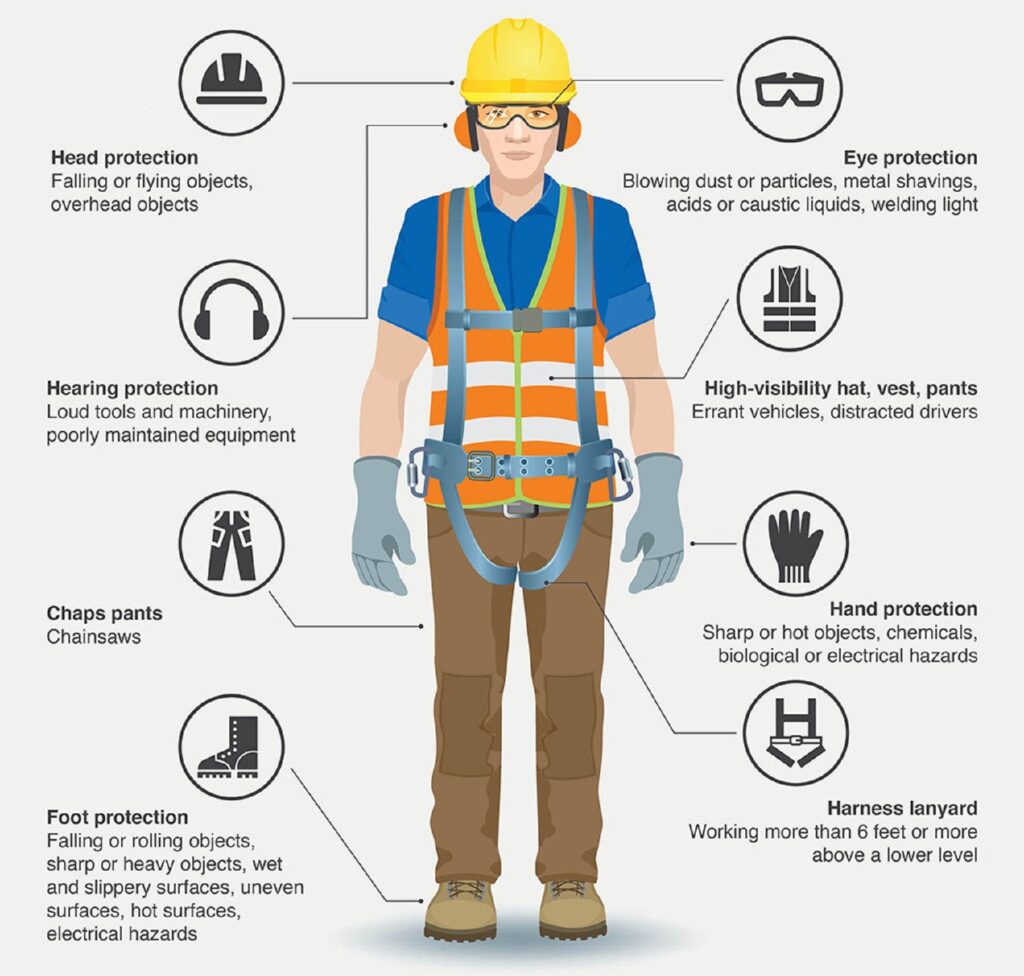

1. Head Protection (Safety Helmets)

- Standards:

- EN 397 (EU): Mandates resistance to vertical impacts (49 J) and penetration (3 kg conical striker).

- ANSI/ISEA Z89.1 (US): Includes Type II helmets for side-impact protection (30.6 J), which EN 397 lacks.

- Key Features:

- Chin straps: Critical for preventing helmet dislodgement during falls (e.g., Hong Kong study found 60% of fall-related head injuries involved unstrapped helmets).

- Comfort: Adjustable liners and lightweight designs (<0.5 kg) improve compliance.

- Smart Helmets: Integrated sensors (e.g., impact detection, GPS) enhance real-time safety monitoring.

2. Eye/Face Protection

- Hazards: Flying debris, chemical splashes, welding sparks.

- PPE Types:

- Goggles (EN 166): Seal tightly against dust/chemicals.

- Face Shields (EN 166): For welding or grinding; must be paired with goggles for aerosols.

3. Respiratory Protection

- Standards:

- EN 149 (FFP2/3): Filters ≥94–99% of particles (e.g., silica dust, COVID-19).

- NIOSH N95 (US): Equivalent to FFP2; requires fit testing.

- Use Cases:

- High-risk (e.g., asbestos): Use P3-rated masks with replaceable filters.

4. Body Protection (Coveralls/Gowns)

- Standards:

- Type 3/4 (EN 14605): Liquid-tight for chemical spills; Type 4 for non-pressurized splashes.

- Type 5/6 (ISO 13982-1): For dust/particulate protection (e.g., asbestos).

- Materials: Breathable fabrics (EN ISO 11092) reduce heat stress.

5. Hand/Foot Protection

- Gloves:

- EN 388: Abrasion/cut resistance (e.g., for handling sharp materials).

- EN 374: Chemical-resistant (e.g., epoxy, solvents).

- Safety Boots (EN ISO 20345): Must have steel toes, slip-resistant soles, and puncture resistance.

6. Fall Protection (Harnesses/Lanyards)

- Standards: EN 361 (full-body harnesses) + EN 355 (energy absorbers).

- Inspection: Check for wear, fraying, and buckle integrity before each use.

7. Compliance & Best Practices

- Training: Workers must understand PPE usage, maintenance (e.g., cleaning masks), and limitations.

- Monitoring:

- AI/Computer Vision: Detects non-compliance (e.g., missing helmets) in real-time.

- IoT Sensors: Track PPE usage and environmental hazards (e.g., gas leaks).

- Behavioral Interventions: Frameworks like BBS (Behavior-Based Safety) address discomfort and improve adherence.

8. Special Considerations for COVID-19

- Masks: FFP2/N95 for high-risk settings; surgical masks for moderate risk.

- Disposable Coveralls: Type 4+EN 14126 for viral protection (tested per ISO 16604).

Conclusion

Prioritize PPE that matches hazard type (e.g., chemical vs. impact) and certification standards. Combine engineering controls (e.g., ventilation) with PPE for layered protection. Regularly audit PPE conditions and worker compliance using checklists or technology.