Introduction: What are Insulating Gloves?

Electrical insulating gloves are personal protective equipment (PPE) designed to protect workers from electric shock when working on or near energized electrical components. They are a critical last line of defense.

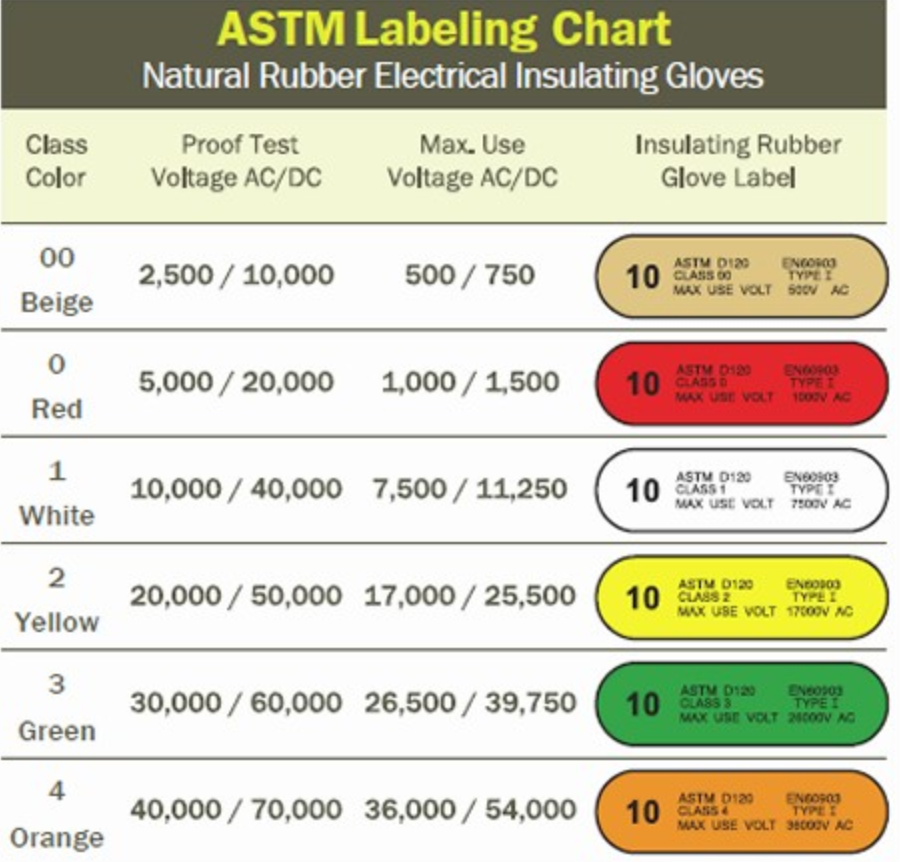

The “grades” or “classes” (the terms are used interchangeably) are defined by the ASTM D120 standard, which is the primary governing standard in North America. The class number corresponds directly to the maximum allowable use voltage the glove is certified to withstand.

Detailed Breakdown of Each Grade

The following table provides a clear overview before we dive into the into the details.

| ASTM Class | Color Code | Max AC Use Voltage (V) | Max DC Use Voltage (V) | Proof Test Voltage (AC, V) | Typical Applications |

|---|---|---|---|---|---|

| 00 | Beige | 500 V | 750 V | 2,500 V | Low-voltage control circuits, low-energy circuits. |

| 0 | Red | 1,000 V | 1,500 V | 5,000 V | Common for 480V/600V systems, residential wiring. |

| 1 | White | 7,500 V | 11,250 V | 10,000 V | Distribution work up to 4.16kV, common for utility linemen. |

| 2 | Yellow | 17,000 V | 25,500 V | 20,000 V | Higher distribution voltages, sub-transmission. |

| 3 | Green | 26,500 V | 39,750 V | 30,000 V | Transmission line work, higher-voltage substations. |

| 4 | Orange | Orange | 36,000 V | 54,000 V | 40,000 V |

Key Terms Explained:

- Maximum Use Voltage (AC/DC): This is the maximum nominal system voltage on which the gloves can be safely used. You must never exceed this voltage. It is not the voltage at which the glove will fail; it has a significant safety margin built-in.

- Proof Test Voltage: This is a higher voltage that brand-new gloves are subjected to by the manufacturer to ensure they meet the standard’s requirements before being sold. It is a quality control test.

- Color Code: A visual identifier stitched into the glove or on a label, allowing for quick and easy identification of the glove’s class in the field.

In-Depth Look at Each Class

Class 00 (Beige)

- Meaning: Provides the lowest level of voltage protection.

- Application: Intended for very low-voltage environments. Ideal for work on control panels, instrumentation, low-voltage industrial equipment (e.g., below 600V), and any situation where there is a risk of contact with circuits under 500V AC. Their thinner material offers better dexterity.

Class 0 (Red)

- Meaning: The most common class for general low-voltage industrial and commercial work.

- Application: Standard protection for working on 480V and 600V systems, which are ubiquitous in industrial facilities and commercial buildings. Also suitable for residential 120/240V systems, though often considered overkill if no other hazards exist.

Class 1 (White)

- Meaning: The entry-level glove for utility and high-voltage work.

- Application: Used by electrical utility linemen and technicians for work on distribution systems typically ranging from 4 kV to 7.5 kV. This is the minimum class for working on most overhead power lines you see on neighborhood streets.

Class 2 (Yellow)

- Meaning: Designed for medium-high voltage applications.

- Application: Used on distribution feeders and sub-transmission lines operating at voltages up to 17 kV. Common for utility crews working on taller poles and in substations.

Class 3 (Green)

- Meaning: For high-voltage transmission work.

- Application: Protects workers on transmission-level circuits up to 26.5 kV. These are the larger power lines carried on tall metal towers.

Class 4 (Orange)

- Meaning: Provides the highest level of voltage protection available in rubber insulating gloves.

- Application: Reserved for extra-high-voltage (EHV) transmission lines and equipment operating up to 36 kV. Due to their thickness, they offer less dexterity and are only used when absolutely necessary for the voltage level.

Crucial Safety Standards and Usage Rules

Simply knowing the class is not enough. Proper use is governed by strict safety protocols, primarily outlined in OSHA 29 CFR 1910.137 (for general industry) and OSHA 29 CFR 1926.97 (for construction), which mandate adherence to the ASTM standards.

Here are the non-negotiable safety rules:

- Leather Protectors Are Mandatory: Insulating gloves must always be worn with an outer leather or arc-rated protector glove. The protector guards the delicate rubber from cuts, abrasions, and punctures. It also provides some additional protection against flash burns.

- Regular In-Service Air Tests (Before Each Use): Before donning the gloves, the worker must perform an air test. Inflate the glove by rolling the cuff tightly and squeezing or rolling the glove to trap air. Listen for leaks and watch for bulges that indicate weakness or damage.

- Periodic Electrical Re-Testing (Every 6 Months!): OSHA mandates that all electrical insulating gloves be taken out of service and electrically tested by an accredited laboratory at least every 6 months. After passing this dielectric test, the glove is stamped with the test date. Using gloves without a current test date sticker is a violation.

- Visual Inspection: Inspect the gloves thoroughly for any signs of damage, including cuts, tears, ozone checking (a cracking pattern), embedded foreign objects, or swelling.

- Proper Sizing and Fit: Gloves must fit correctly to avoid excessive stress on the material and to maintain dexterity.

- Storage: Store gloves in their protective bag away from direct sunlight, extreme temperatures, ozone sources (like motors), and chemicals.